Lean/IPD Hold the Key to Rapid Expansin for Manufacturers

Greg Fox

Miller Valentine Construction

It’s too early to definitively state how the coronavirus pandemic will reshape the U.S. economy over the long term. But one bright spot could be an upswing in American manufacturing. After the pandemic exposed the fragility of international supply chains, the potential for reshoring manufacturing to the U.S. is becoming a very real possibility.

For manufacturers, this could create opportunities to expand, and fast. Owners and developers who want to rapidly scale up for less cost will need to look beyond traditional construction methods. They should instead invest in collaborative contracting using lean principles and integrated project delivery (IPD) methods.

For manufacturers, this could create opportunities to expand, and fast. Owners and developers who want to rapidly scale up for less cost will need to look beyond traditional construction methods. They should instead invest in collaborative contracting using lean principles and integrated project delivery (IPD) methods.

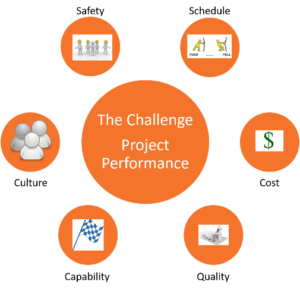

Lean/IPD projects perform better than traditional projects across every measure of success. On average, they cost less, are completed faster, are of higher quality, and deliver a better overall experience for owners and the project trade partners. A recent analysis by McKinsey & Company released in January 2020 found a 15 to 20 percent improvement in cost and schedule performance on eight projects that used Lean/IPD methods.

Selecting the Right Team

One of the hallmarks of a Lean/IPD project is collaboration. Key stakeholders—typically the owner, architect, trade partners, builders, suppliers, engineers, and major equipment manufacturers—are brought to the table at project inception. The team pools their respective expertise and knowledge to design, engineer, and construct a project that supports the owner’s goals within an agreed-to budget.

For this to work, Lean/IPD projects require greater collaboration, transparency, and trust than traditional delivery methods. Naturally, not all companies are well-suited for this model. As a result, relevant experience and technical capabilities aren’t the only qualifiers that owners need to assess when forming their team. Other factors should include:

- Experience with Lean/IPD thinking and logic

- A corporate culture that emphasizes collaboration as well as continuous learning and improvement

- A willingness to embrace open-book accounting and other transparency measures

- Evidence of innovation and collaboration within their company and industry

- A demonstrated ability to accurately forecast hours and costs

- An emphasis on accountability

- Perhaps the most important factor—and the hardest to define in an RFP—is team chemistry. You need to trust your partners, and they need to trust each other. Trust is required to foster open communication, collective decision-making, and innovation.

For that reason, owners need to shift from traditional procurement methods that emphasize standardization to a more hands-on approach, including interviewing the actual team members who will work on the project. Only then can they assess which partners can best work together to address the needs, challenges, and risks of the project.

OEDA Congratulates Graduates of the 2025 Ohio Basic Economic Development Course

OEDA Congratulates Graduates of the 2025 Ohio Basic Economic Development Course DUBLIN, OH – The Ohio Economic Development Association (OEDA) proudly congratulates the more than 85 participants who successfully completed the 2025 Ohio Basic Economic Development Course...

OEDA Begins Strategic Planning Amid Record Growth + Program Expansion

FOR IMMEDIATE RELEASE RFP now open for OEDA’s next strategic plan; proposals due July 1, 2025 COLUMBUS, OH; Tuesday, June 3, 2025 — The Ohio Economic Development Association (OEDA) has released a Request for Proposals (RFP) to develop a new strategic plan, its first...

OEDA seeks host communities for its Annual Summit

For Immediate Release OEDA seeks host communities for its Annual Summit For the first time, location proposals sought for 400+ attendee conference COLUMBUS, OHIO – TUESDAY, NOVEMBER 12 – Today, the Ohio Economic Development Association (OEDA) announced that is...